|

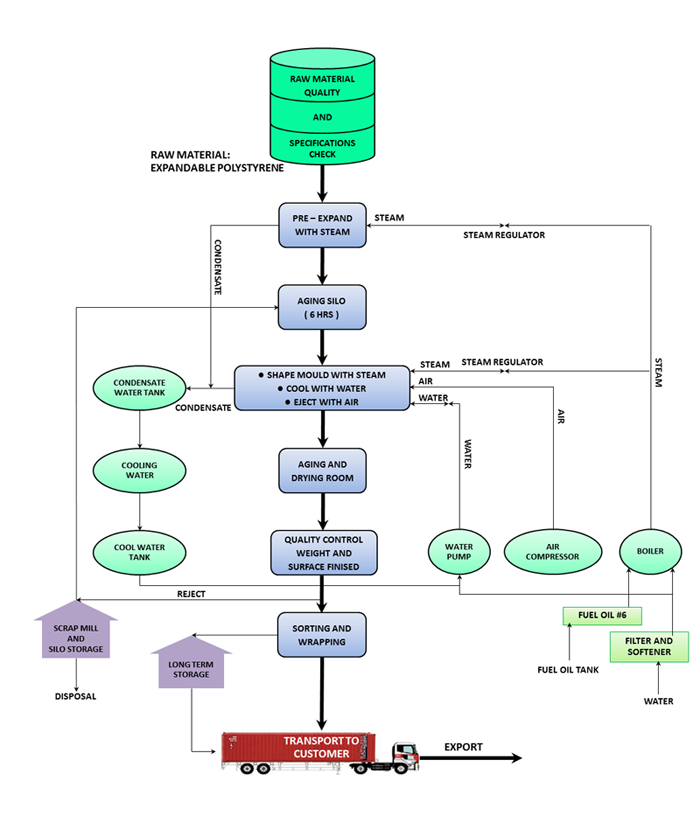

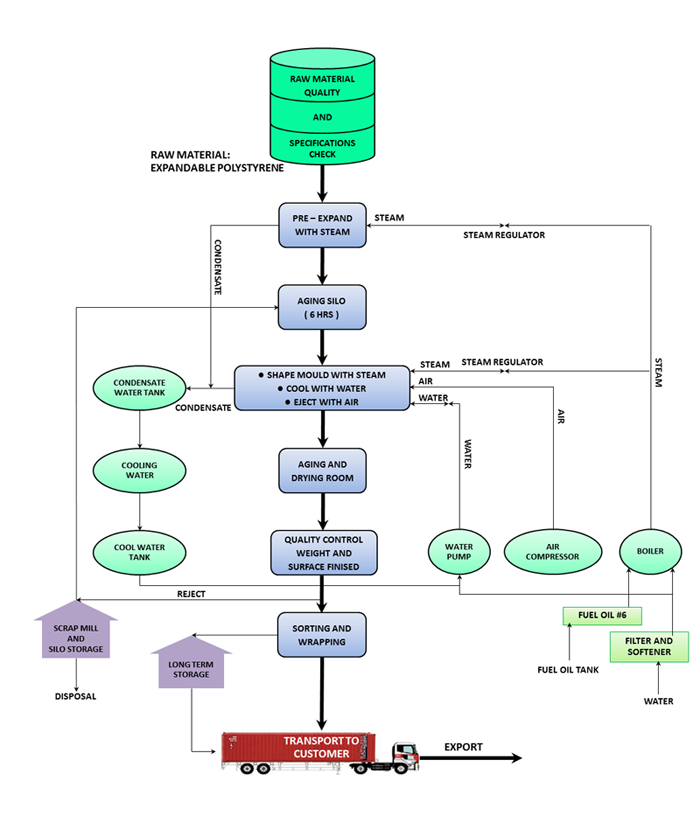

Our Process

Manufacturing Process

ERP System

What is ERP?

Enterprise resource planning (ERP) is the industry term used to describe a broad set of activities supported by multi-module application software that helps a manufacturer or other business manage the important parts of its business. These parts can include product planning, parts purchasing, maintaining inventories, interacting with suppliers, providing customer service, and tracking orders. ERP can also include application modules for the finance and human resources aspects of a business.

The Goal of ERP System - The goal of ERP is to improve and streamline internal business processes, which typically requires reengineering of current business processes.

ERP Benefits

Improved Visibility

With manufacturing ERP systems, all departments across an entire business can access and view the same consistent and accurate data in real time. So, everyone from the engineering teams to the production floor to the purchasing and finance departments has complete visibility into designs and plans, production status, quality control, inventory, cost of goods sold, and more. This enables better, smoother coordination and execution of all related processes and procedures.

Increased Efficiency

Manufacturing ERP software allows firms to track all supply chain activities in great detail from start to finish a task that would be nearly impossible otherwise. So, procedures and processes that hinder productivity and slow down the design, creation, and delivery of goods can be instantly identified, and corrective action can be swiftly taken to ensure optimum efficiency.

On-time Delivery

Improved control over components inventory, more accurate demand planning, streamlined production scheduling, and more effective coordination of distribution channels all key benefits of manufacturing ERP software systems enable companies to improve on-time delivery of products, a critical performance metric for today's manufacturers.

Enhanced Product Quality

Manufacturing ERP software systems make it easier for businesses to monitor product defects and problems, pinpoint exactly where in the design or production process the issue is occurring, and take the needed steps to ensure products of the utmost quality. This, in turn, will boost sales, customer satisfaction, and profits.

Reduced Costs

Manufacturing ERP systems reduce costs in many ways. Increased worker productivity minimizes overtime and related labor and payroll expenses. Enhanced precision in production floor processes reduces the scrap and re-work that can drain financial resources. Better tracking of components and turnover of finished goods, combined with more accurate demand planning, eliminate costly excess inventory. And, improved visibility into all financial aspects of production can help identify potential areas for savings and reduce cost of goods sold.

Improve Collaboration

Many manufacturing ERP systems enable companies to share important production-related data with not only internal employees, but with external constituents such as vendors, suppliers, and distributors. This improves communication and enables better coordination of activities among these key business partners.

|

Process

Process